Blog Post

Pipe Flanges 101

Nov. 23, 2022

Introduction to Pipe Flanges

Whether it's an oil and gas pipeline, irrigation in agriculture, or a piping system for chemical processing, connecting pipes is a common occurrence in a variety of industries. Regardless of the purpose and type of fluid being transferred, the connections must be secure with minimal to no leakage ensuring safety and efficiency. Pipe flanges play a vital role in this process.

What are Pipe Flanges?

Pipe flanges are a component used with a gasket and bolts to create a connection in a piping system. Flanges are available in different sizes and materials, such as stainless steel, cast iron, aluminum, brass, and bronze.

Pipe flanges are the second most common method of joining pipes together. Welding is the most common method of connection, but the benefit of flanges is they can be taken apart easily. This provides flexibility for maintenance, shipping, and inspection. Pipe flanges are also assembled with moderate torque, which makes them easier to fit in tight spaces where a wrench may not have clearance.

How Do Pipe Flanges Work?

Pipe flanges are used to connect pipe components, such as pipes, fittings, and valves. There is a gasket in the middle of the flange, and bolts are used to join the pipe with the other components. The piping is attached to the flange by a threaded connection, a weld, or a stub end.

Common Types of Pipe Flanges

There are different types of pipe flanges depending on the application and the strength required of the flange joint. The six most common types of flanges are weld neck, slip-on, socket weld, lap joint, threaded, and blind.

Weld Neck

Weld neck flanges have a long, tapered hub that transfers stress from the flange to the pipe for reinforcement. These types of flanges are used in high-pressure and high-temperature applications and are commonly used for process piping.

Weld neck flanges have a long, tapered hub that transfers stress from the flange to the pipe for reinforcement. These types of flanges are used in high-pressure and high-temperature applications and are commonly used for process piping.

Slip On

As the name suggests, slip-on flanges slide over the end of the pipe. The outer diameter of the pipe is matched with the flange and then welded in place. Slip-on flanges are suitable for low-pressure and temperature applications.

As the name suggests, slip-on flanges slide over the end of the pipe. The outer diameter of the pipe is matched with the flange and then welded in place. Slip-on flanges are suitable for low-pressure and temperature applications.

Socket Weld

Socket-weld flanges are easy to install. The pipe is placed into the flange and welded into place. These types of flanges are best suited for small pipe diameters used in low-temperature and low-pressure applications.

Lap Joint

Also called a floating flange, lap joint flanges are made up of a stub end, which is welded to the pipe, and a backing flange that moves freely over the pipe. This type of flange is used where space is limited, and frequent dismantling is required.

Also called a floating flange, lap joint flanges are made up of a stub end, which is welded to the pipe, and a backing flange that moves freely over the pipe. This type of flange is used where space is limited, and frequent dismantling is required.

Threaded

Threaded flanges are also called screwed flanges. These flanges have threads inside that fit with the male threads on the pipe. No welding is required for this simple connection. Threaded flanges are not suitable for high temperatures and pressure. They are typically used in air and water utility services.

Threaded flanges are also called screwed flanges. These flanges have threads inside that fit with the male threads on the pipe. No welding is required for this simple connection. Threaded flanges are not suitable for high temperatures and pressure. They are typically used in air and water utility services.

Blind

A blind flange is essentially a blank disc used to close the ends of pipes or valves, or for flow pressure testing. Blind flanges have a high-pressure capacity. They are easy to remove, providing easy access to a line even after sealing.

Other special types of flanges

In addition, there are other special types of pipe flanges, including nipoflanges, weldoflanges, expanders, and reducers.

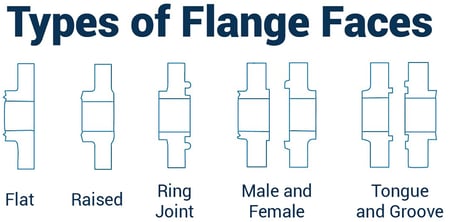

Flange Faces

The flange design is only one aspect to consider when selecting a pipe flange. The flange face, which is the mating surface of the flange, determines what gasket is needed to complete the installation. There are five types of flange faces: flat, raised, ring joint, male and female, and tongue and groove.

Flat FaceAppropriately named, flat-face flanges have a flat, even surface with a full-face gasket in contact with most of the flange surface.

Raised FaceRaised face flanges have a raised portion around the bore. The pressure-temperature rating, called a flange class, determines the height of the raised face. An inside bore circle gasket is used with a raised face flange.

Ring Joint FaceUsed in high-pressure and high-temperature applications, ring joint face flanges feature a specially designed groove for a metal gasket to maintain the seal.

Male and FemaleMale and female flanges are composed of two faces. The male flange face has a raised ring, and the female flange face has a matching depression. The gasket is retained on the female face of the flange.

Tongue and GrooveTongue and groove flanges are similar to male and female flange faces. They also have a matching groove and a depression, but they differ in the inside diameter of the tongue, and the groove does not extend into the flange base.

ANSI vs TTMA

Pipe flanges must be properly fabricated for safety and efficacy. As a result, organizations such as the American National Standard Institute (ANSI) and Truck Trailer Manufacturers Association, Inc. (TTMA) have developed standards for pipe flanges and other products.

ANSI is a private, non-profit organization that oversees the guidelines and standards of goods and services for the U.S. Since some flanges must be able to sustain high pressures, ANSI provides standards for manufacturers to test flanges before marketing.

TTMA is a trade association whose members are manufacturers of truck trailers and their suppliers. The association provides recommended practices for trailers and trailer-related products. In terms of pipe flanges, TTMA has a specific flange pattern for consistency on tank trucks and trailers.

How to Get a Proper Flange Fit

Selecting the proper flange for any application is imperative for optimal performance. The flange must fit the pipe joint properly to work effectively and prevent costly spills. A few items to consider for a proper fit include:

- Outside diameter: The distance between two opposite edges of the flange face

- Nominal bore size: A measurement of the flange connector's inner diameter

- Bolt circle diameter: Measured center to center, the distance between opposite bolt holes

- Thickness: Used to help determine the amount of pressure a flange can tolerate, thickness refers to the depth of the outer rim

- Pipe Size: Describes the size of the pipe the flange connects to

Pipe Flange Classifications

Different classifications are used to determine a flange’s ability to withstand temperatures and pressures. Classifications are designated with a number and # or lb. The most common classifications are 150#, 300#, 600#, 900#, 1500#, 2500#. The tolerances of these flanges vary based on materials, design, size, etc. However, one consistency is the fact that pressure ratings decrease as temperature increases.

Flange Markings

The American Society of Mechanical Engineers (ASME) established global standards for pipe flanges. These standards include markings on the side of the flange to make comparisons and replacements easier. Pipe flanges are marked in this order:

- Manufacturer logo

- ASTM material code

- Material grade

- Service rating (pressure-temperature class)

- Size

- Thickness (schedule)

- Heat number

- Special designations, if any, such as QT for quenched and tempered, or W for repair by welding

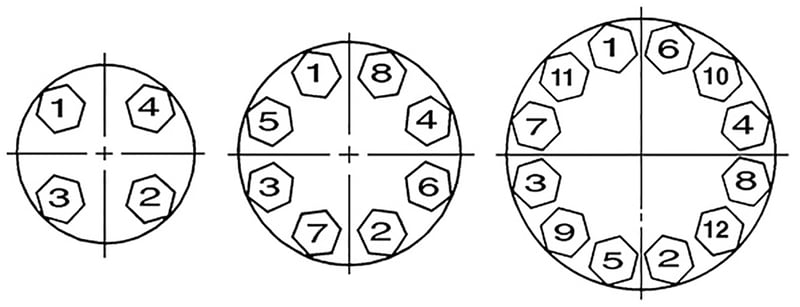

Flange Bolt Hole Patterns

The pressure rating of a flange will determine the size, spacing, and number of bolts required for a pipe flange. It is important to use the appropriate gaskets and bolts and to secure the bolts using the proper sequence as depicted in the diagram. Watch this video to view the flange bolt tightening sequence for 4, 8, and 12 bolts.

The pressure rating of a flange will determine the size, spacing, and number of bolts required for a pipe flange. It is important to use the appropriate gaskets and bolts and to secure the bolts using the proper sequence as depicted in the diagram. Watch this video to view the flange bolt tightening sequence for 4, 8, and 12 bolts.

Compatibility with Dixon’s Turned Back Nipples

In addition to a variety of pipe flanges, Dixon offers King Turned Back Weld-to-Metal Hose Nipples compatible with lap-joint flanges.

Features:

- MSS Length

- Phono-finish face (type CS), except 10" and 12" have a smooth face (type C)

Summary

Although we focused on piping systems, it is important to note that all of the flanges described in this post can also be used in standard industrial hose applications.

Understanding the function, design, and characteristics of pipe flanges is essential for a successful piping system. Knowing the different flange types, faces, classifications, and markings are a great start to making The Right Connection®. However, it is impossible to outline every possible detail and configuration in this post, so Dixon is here to help with your specific application. For more information, visit dixonvalve.com or call 877.963.4966.

CN | en

CN | en